Weinig Powermat 700

5 Head Moulder

FOR MORE INFORMATION, YOU MAY GET IN CONTACT WITH YOUR GERMAN TECH MACHINERY SALES REPRESENTATIVE

The Powermat 700

is designed with a revolutionary new operating concept which no other molder can offer. The result: improved ease of operation and very short setup times offer the highest degree of flexibility. With these outstanding qualities the new Powermat is the perfect response to the market demands of today and sets a new standard for four sided processing.

CLICK ON THE PICTURES TO ZOOM IN.

The WEINIG Powermat series provides :

- Innovative machine technology

- High production accuracy

- High level of work safety

- Modular design

- Made in Germany

The WEINIG Powermat 700 provides:

- Highly user-friendly

- Enormous savings in setup time

- High level of repetition precision

- Outstanding surface quality

- High resource efficiency

- Excellent safety features

- Sustainable machine concept

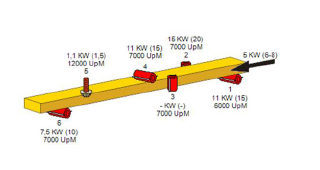

1618646 Tool arrangement no. 017

Operating Comfort Set:

A unique operating concept with scales and clear measurements located at all

relevant setting points in the machine. All setup requirements can be performed

either wrench-free or with the assistance of only two hand tools.

This results in ergonomic and safe set up for the operator, short set up times

and high quality of the end product.

TECHNICAL DATA :

Working width (with tool cutting circle 93-125mm) 20-260 mm

With tool lengths of more than 240 mm, speed max 7000 rpm

Incl. air pad system in the machine table

When using conventional cutting spindles, the horizontal tool holder

can be used in combination with Weinig special cutterheads for

smooth planing with working widths over 230-260 mm

1140694

Cost component per spindle for 260 mm working width

Working height (with tool cutting circle 93mm on top spindle) 10 – 200 mm

Quick disconnect dust extraction hose

Your advantage:

- Reduced setup time and greater safety due to improved

access to the left spindle and the area in front of it

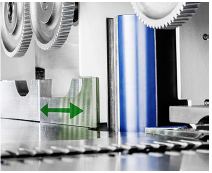

35973 Two lateral roller pressure in front of left spindle revolving and spring mounted

1649093 Split pressure shoe in front of top spindle with horizontal plane of adjustment to the tool cutting circle and receding from the tool, spring loaded

Your advantages:

- Precise positioning to the tool diameter for ideal control of work pieces

- No need to change the chip breaker shoe

256346 Pressure shoe in front of and guide after top spindle with electronic

digital displays integrated in Memory function or PowerCom.

SPINDLES IN GENERAL

118308 All spindles with highly concentric running

Optimized flow of dust and wood chips due to aerodynamic hood design

Your advantages:

- Energy savings due to reduced performance requirements from the dust extraction system

- Reduced noise emission

Air volume requirement per spindle with hose Ø 160 mm 1680 – 1920 m3/h

and air speed of 23-26 m/sec.

FEED SYSTEM

1617184 Feed speed electronically variable incl. brake 5 -40 m/min

1004238 Motor 5 kW (6.8 HP)

257733 Feed roller in front of 1st bottom spindle pneumatically moved “up-down”

All feed rollers with quick clamping

Your advantages:

- Quick positioning of feed roller tracking

- Quicker exchange of feed rollers

7133118 Durofer green timber feed rollers for extremely wet and dirty timber, self-cleaning

256409 CNC-controlled adjustment and positioning of feed up/down in

combination with Memory – Function or the PowerCom

FOR MORE INFORMATION, YOU MAY GET IN CONTACT WITH YOUR GERMAN TECH MACHINERY SALES REPRESENTATIVE