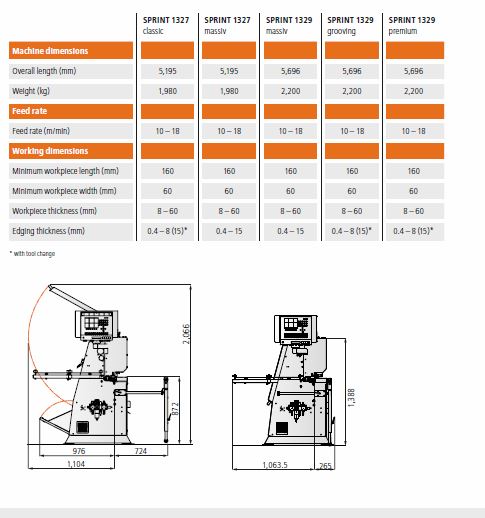

HOLZ-HER SPRINT 1327/1329

The Future of Edgebanding

Designed for highest requirements in terms of quality and flexibility. Various compact models are available for complete processing of state-of-the-art edging and panel material. Program selection allows the machine to be set up without even opening the hood, so that it is ready for production immediately. The HOLZ-HER SPRINT series set the highest, professional standards for edgebanding without compromises.

- Maximum precision and processing reliability for many years with torsionally stiff, welded machine columns.

- Ergonomic operation with rotating and pivoting control panel. Comprehensive program memory with complete storage of all operating data as well as service messages in clear text.

- Fully automatic control of processing machines at the touch of a button using NC servo-axes.

- All five SPRINT models are equipped with our Glu Jet system as a standard feature for razor-thin glue joints, fully equal to any industrial laser edging

Simple Handling – High Productivity

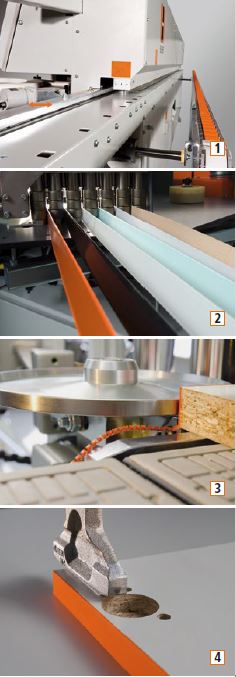

- Long, motor-driven run-in linear guide

For optimum feed of long workpieces. Joint thickness can be adjusted automatically at the touch of a button on the motor-driven run-in linear guide (optional) (Fig. 1). - 6-fold edge feeder

New with sensor for recognition of remaining length and automatic change-over to alternative edging channel. Including auxiliary shaft for feeding in cut-length edging (optional) (Fig. 2). - Radius scraper

Motor-adjustable scraper with two NC servo-axes for optimum adaptation to existing edge tolerances (optional) (Fig. 3). - Nesting package

For concealed hinge holes or trapezoidal work (optional) (Fig. 4). - Transport chain lubrication

Intelligent automatic transport chain lubrication. Sensor-controlled unit, for metering lubrication to match load (optional).

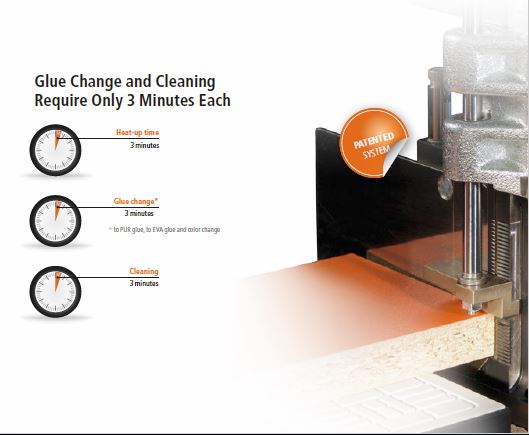

Glu Jet – Zero Joint with Thin Film Technology

The clear advantages of our hybrid technology in combination with the new HOLZ-HER thin film technique make this gluing system the all-rounder for craftsmen and industrial users. Visual zero joints with PUR glue – allowing use in wet areas – are natural for HOLZ-HER customers.

Ultra-thin glue joints, easily equivalent to industrial laser edges, are easy to achieve with the HOLZ-HER Glu Jet system, which also offers unrivaled flexibility.

From state-of-the-art, high gloss edging right up to thick edging cross sections in the solid wood range, HOLZ-HER remains unequaled in terms of appearance, regardless of the material. HOLZ-HER sets tomorrow’s trends today

PUR Glue is the Standard for Professional Cabinet Makers

Industrial technology for every shop – with the Glu Jet System you can process PUR glue on a standard basis; just as simply as EVA glue. Strong arguments for you and your customers:

- No additional glue basin.

- No expensive nitrogen tanks.

- High strength joint for extremely long service life.

- Resistant to heat and water, providing quality advantages in all areas of cabinetmaking.