MARTIN T65

The T65: MARTIN’s interpretation of the premium entry level-class saw.

The T65 combines traditional operating methods with the most modern electronic support. This innovative control structure speeds up work and leads to a more intuitive understanding of the machine’s function by the operator.

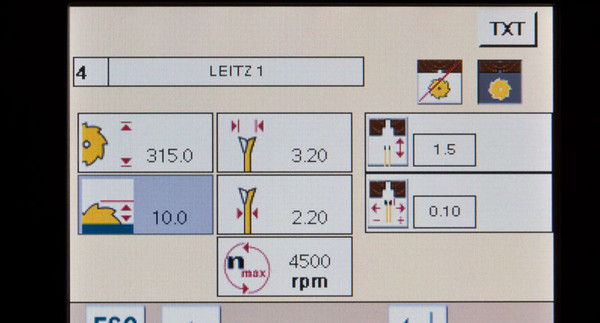

With the proven 5.7“ touchscreen controller at eye level, the operator is guided through individual work processes step by step. Sturdy mechanical design in combination with sophisticated control technology form a well-balanced machine. MARTIN does not only set industry standards when it comes to technology but also when it comes to user-friendliness.

Easy to operate

The operating unit of the T65 is a powerful and user friendly controller. With its 5.7” color touchscreen, this machine sets industry standards as to ease of use, functionality, safety and comfort. All relevant information is visible at a glance. Step-by-step, the operator is prompted through complex work processes leading to more ease of use and more accurate results. The movement of the blade height and angle are electronically controlled on every T65 and it is equipped with the standard MARTIN tool conversion, where the machine always knows the saw blade width and diameter. The machine can also be equipped with an optional motorized rip fence integrated into the controller. With a T65 you can work with up to eight optional linked axes which considerably reduces set-up times.

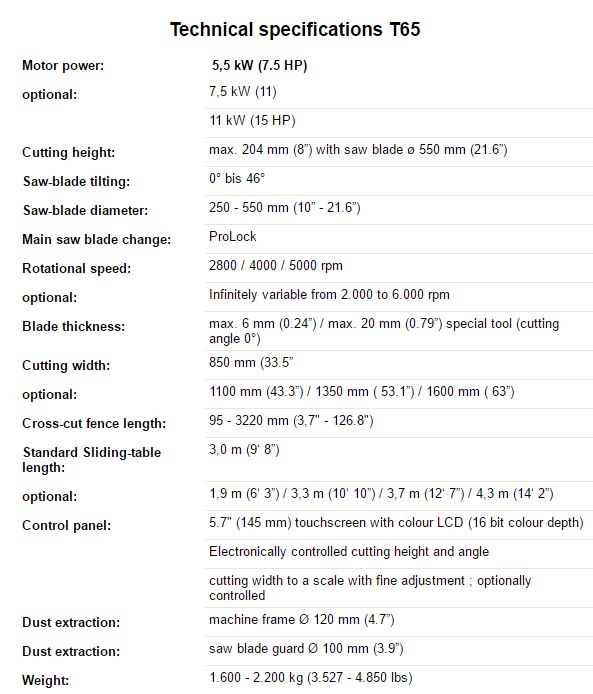

Powerful cut up to 204 mm in height

The massive cutting height of 204 mm and the tilting angle of 0 to 46° provides greater flexibility for complex tasks. With the ProLock-System, the main as well as the scoring saw blades can be replaced quickly and easily. On the T65 the rotational speed is easily changed through an opening in the machine table. With the optional variable speed control the RPM’s can be adjusted to a wide variety of different man-made materials. You simply enter the desired rotational speed of the saw blade without having to turn off the machine.

Technology in detail

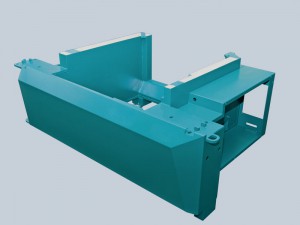

The T65’s solid and heavy machine frame that is reinforced with a concrete composite is unique and in the woodworking machinery industry only to be found on MARTIN machines with this technical perfection. Otto Martin invented this method of construction in the 1920s and had it registered as a patent back then. Today, after 90 years of continual improvement, Martin still uses this simple and effective type of frame construction. The combination of steel and concrete create a high quality machine frame that is unparalleled when it comes to sturdiness, absorbing capacity and torsion resistance. This design has been proven to have up to six times the vibration dampening properties than that of a traditional cast-iron or welded frame.

The MARTIN hardened steel guide system that has been steadily improved since 1959, is the core of every sliding table saw. The unbeatable technical advantage of this system is the permanent smooth and precision guidance of the table. The hardened steel guide strips are permanently lubricated in oil to make sure that the surfaces are unaffected by dust and chips. The hardened guide strips are cleaned every time the operator strokes the table and is the only way to permanently ensure a smooth and easy movement of the sliding table over time. Another important quality characteristic is that no plastic parts were used in the construction of this component; a valuable consideration when it comes to cut quality.

Another unique MARTIN standard is the replaceable table lip that is bolted to the main sliding table extrusion. This makes it easy to repair damage caused by deflected saw blades. The table can also be locked down every 20 mm along the length of the machine. Whether you work with various cutting devices or load the table down with heavy material, the MARTIN sliding table is always positioned where you need it.

Precise rip fence

The rip fence of the T65 can easily be manually moved and thanks to the standard fine adjustment can be set very precisely. The precision rip fence’s wear-free grooved ball-bearing guide system further ensures maximum precision and allows the fence to glide over the table smoothly and without support. If large panels have to be cut, where the machine table must be cleared, the rip fence can be removed from the carriage in no time at all. With the optional hand-wheel, the cutting dimension can be indicated from the operating position over the full cutting width. The digital display (resolution 0.1 mm) integrated in the control ensures maximum precision. You can also offset the workpiece thickness in the controller so that the readout for the rip fence references the top of the workpiece instead of the bottom side, allowing the operator to make precise bevelled cuts. Compound miter cuts to the left side of the blade are reduced to childs play. The optional motorized rip fence quickly (approx. 300 mm per second) and precisely (0.1 mm) handles the entries made in the controller. Additionally, the machine independently recognizes the danger zone around the saw blade and has the rip fence slowly move towards the blade line to increase operator safety.

Precise cross-cut fence

Experienced woodworkers say that fine adjustment is a very important quality feature on a precise cross-cut fence. It is quite common that the cutting dimension has to be altered just a little; without fine adjustment… no chance! Every T65 is equipped with a magnifying glass, an easy to read scale and standard fine adjustment of the stop elements. Another convincing detail of the cross-cut fence is the smooth and precision guidance of the stop elements. The quality ball bearing construction of the stops allow them to glide easily from one position to the next. The cross-cut fence can be positioned in either the forward or rear position on the cross-cut table. In either position the miter angle can be infinitly adjusted to a scale up to 50°. The exact compensated calculation of the cut is performed by the controller.

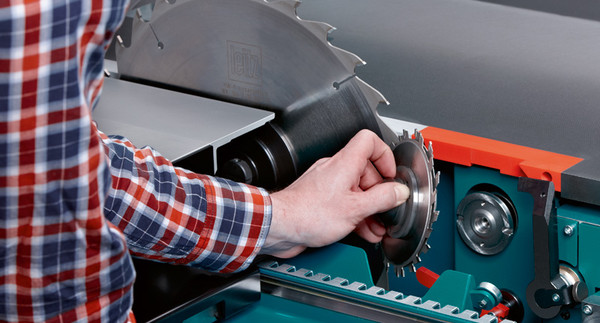

Scoring saw for all requirements

A scoring saw prevents workpiece tear-out on the edges of decorative veneered and laminated panels. Two scoring units are available for the T65. Both units can be turned on and off and positioned electrically via the operator control panel while the lifting and lowering is done pneumatically.

The 2-axis system is completely user-friendly. Full integration into the controller facilitates the input of all necessary settings. The left/right positioning of the scoring saw in relation to the right shoulder of the main blade and the scoring height is adjusted automatically. The kerf width is adjusted with stacked shims. If you combine the 2-axis scoring saw with the T6522 ScribeMaster saw blade system, the kerf width can be adjusted in a matter of seconds. With inserted scoring saw blades you can use main saw blades of up to 500 mm in diameter. If you remove the scoring saw blades and the flange you can easily work with saw blades of up to 550 mm in diameter.

The MARTIN 3-axis scoring saw system is fully integrated in the controller and facilitates the input of all necessary settings. The fully integrated scoring saw is linked to the controllers tool menu, allowing the automatic positioning of the scoring saw width to match every main saw blade that has previously been entered into the controller. The system needs to be calibrated only once. Time-consuming sample cuts are avoided almost completely.