COLUMBUS VACUFLEX

SIMPLE VACUUM TECHNOLOGY FACILITATES CUSTOM FORM-GLUING AND FORM-VENEERING

- Laminated Bending

- Laminating and veneering of any form and shape with wood and board materials such as: bendy plywood, plywood, thick sawn veneer, MDF, etc.

- Flat Pressing & Bonding

- Flat pressing, veneering and bonding of various materials such as: wooden board materials, recycled wood, composite materials, honeycomb boards, glass, etc.

SIMPLE VACUUM TECHNOLOGY FACILITATES CUSTOM FORM-GLUING AND FORM-VENEERING

In high-end shop-construction, interior design, and in the construction and decoration of public spaces, rounded and curled forms are used more and more often. Examples for this are bar consoles, counter tops, room dividers, etc.

VACUFLEX lets you effortlessly create these parts with only one template (no counter-template necessary).

The effortless veneering/coating of rounded or curled work pieces is another application of VACUFLEX!

The VACUFLEX unit is open along one of its shorter sides to receive the work piece. It can easily be sealed off using the included sealing rail.

VACUFLEX is especially suitable for the form-gluing and form-veneering of work pieces; the necessary layers are simply inserted into the vacuum pouch together with the templates.

Technical Details

Material:

Yarn type: PES (Polyethersulfon)

Yarn weight: 1100 dtex

Coated fabric: rubber (neoprene)

Thickness: 0,9 mm

Warp tensile strength: 4000 N/5 cm (ISO 1421/1977)

Warp tear strength: ca. 1800 N (ISO 4674/1977)

Fill elongation at break: 25 % (ISO 1421/1977)

Thermal impact: min. – 30 °C, max. + 80 °C

Standard value:

Reference layer thickness for HDF-R :100 (radius 400 mm layer thickness 4 mm)

Production capacity:

Form-gluing:

depending on the type of glue used: 1 – 8 hours per pressing

Form-veneering:

depending on the type of glue used: 15 min – 1 hour per pressing

EQUIPMENT AND SCOPE OF DELIVERY

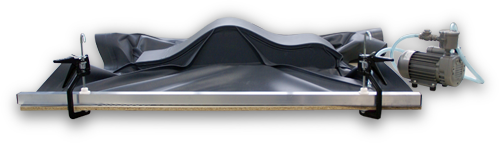

VACUFLEX consists of a vacuum pouch of various sizes, manufactured from a highly durable polyester fabric that is rubberized on both sides. The unit has a vacuum connection.

The included vacuum pump TF 8 (suction force 8 m³/hour) is ideal for use with the unit. The unit is constructed for continuous use. (The vacuum pump is turned on throughout the entire pressing process and maintains a consistent vacuum inside the pouch)

VACUFLEX is delivered with a sealing rail (including sealing wedges) used to tightly close the open side of the pouch.

Sizes

VACUUM-PUMP TF 8

with 8 m³ suction force/hour

electric connection 230 V

90 % absolute vacuum

VACUFLEX 300

Effective useful surface

Length: 3000 mm

Width: 1300 mm

VACUFLEX 400

Effective useful surface

Length: 4000 mm

Width: 1300 mm

VACUFLEX 300 S

Effective useful surface

Length: 3000 mm

Width: 2000 mm

VACUFLEX 400 S

Effective useful surface

Length: 4000 mm

Width: 2000 mm

The vacuum pouches can be manufactured to fit your custom needs.

The units are maintenance-free.

The technical data contained hereing is subject to modification.