Gannomat ProTec

CNC Machining Center

CNC precision machinig center for complete processing – Drilling, Grooving, Routing. Compact design and high performance technology with through feed technique for cabinets, furniture, interior design and much more. Compact – Stronger – Faster.

- Large (1000x5600x60mm) and small (60x250x6mm) workpiece dimension

- small footprint requirement: less than 33m3

- Gentle workpiece handling by air cushion

- precision through double laser measurement and workpiece straightening

- Fast processing through 21/23 drilling spindles

- 21/23 drilling spindles for zero setting times

- strong routing unit 5,5 kW (S1), option

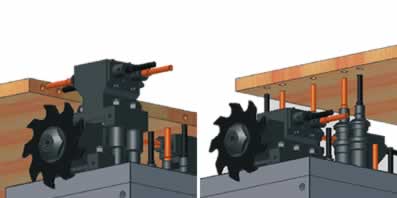

- Stable grooving unit till 8,3mm saw blade width

- Automatic tool changer for routing unit, option

Features and Benefits

| Vertical machining from underneath |

Advantages of the horizontal or lying workpiece transport and processing from the bottom are:

| • | The workpiece weight is spread on the largest workpiece surface, herewith the relatively thin workpiece edge with the already glued on edge material is protected. |

| • | Very easy loading and unloading of long and heavy workpieces (e.g. countertops). |

| • | The zero point is always at the bottom edge of the workpiece. |

| • | Precise and constant drilling, grooving and routing depth, even when tolerances in workpiece thickness are given, because the workpiece is referenced to the machine steel table. |

| • | The workpiece is protected, because the outer surface of the finished workpiece faces upwards. |

| • | Chips and sawdust automatically fall out of holes, grooves and routings, therefore e.g. clean holes are given for inserting dowels, hinges, fittings and other hardware. |

| • | Very good dust extraction results. |

Gentle workpiece processing through air-jets

| Massive supporting table with Air-Jet-Table, the most precise and gentle drilling reference surface. |

Universal application in panel processing and solid wood processing

| Precision drilling, grooving and routing for efficient panel and solid wood processing. |

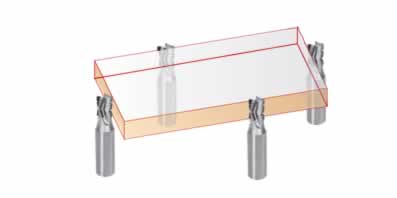

4 side formatting

A precise routing around at all four edges of the workpiece is given and herewith the full formatting of panel material.

Simply programm the the wished excess length.

Space requirement 3,3 m²

| • | Width (X): 2200 mm |

| • | Depth (Y): 1484 mm |

| • | Height (Z): 1409 mm |

The ProTec can be placed at the left side against a wall.

Please enter your contact details below to download the brochure