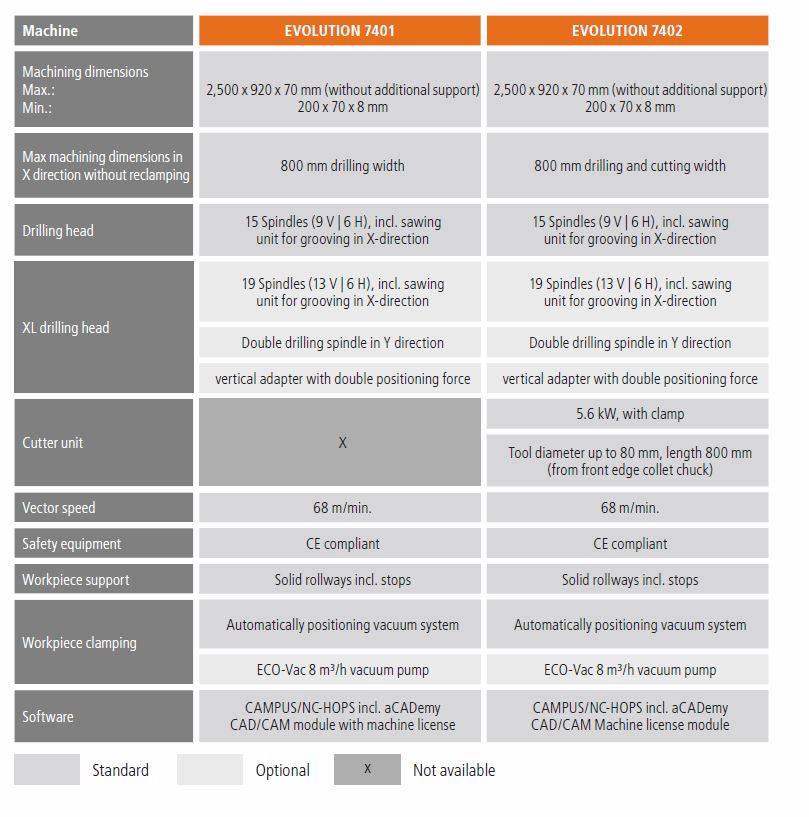

HOLZ-HER EVOLUTION 7401/7402

Intelligent solutions for drilling, grooving and milling

The technical data for the EVOLUTION series speaks for itself:

- Workpieces with height up to 920 mm and unlimited length can be processed with the smallest possible space requirements.

- Material thicknesses of 8 to 70 mm make the vertical machining centers from HOLZ-HER all-round machines for producing everything from drawers to body parts, furniture fronts and rear walls.

- Campus Software Package guarantees simple and clear programming.

- The solid design of the EVOLUTION series guarantees short cycle times and maximum machining quality.

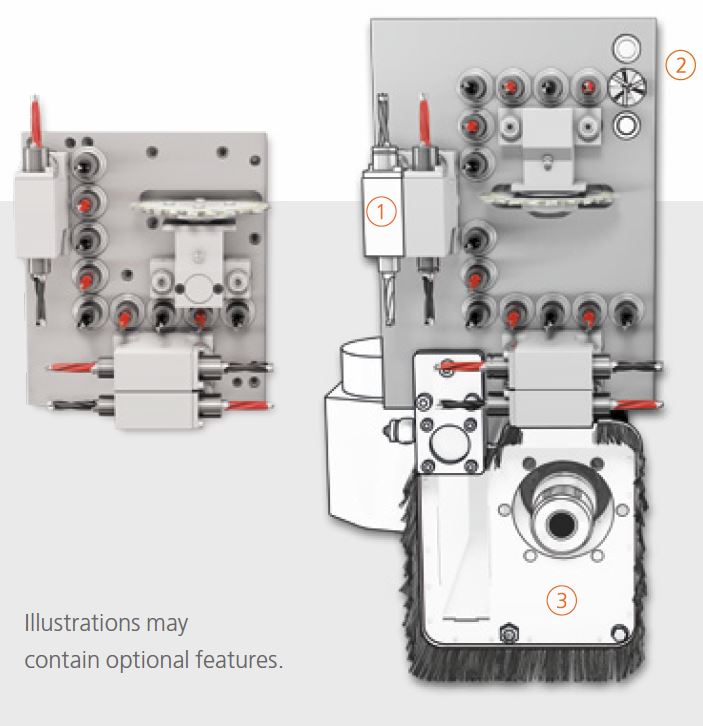

Fully equipped drilling head

- 15 drilling spindles for 5 in-line holes each in X and Y directions as well as 6 horizontal drills and integrated sawing unit for quick and precise results (Fig. bottom left).

- As an option, the EVOLUTION series can also be equipped for even higher performance with an XL-drilling head, with up to 22 drilling spindles and grooving saw (Fig. bottom right).

- XL drilling head supplements

1. Additional double drilling spindle in Y direction

2. Vertical adapter with extra strong spindle

3. Cutting spindle (on EVOLUTION 7402 only)

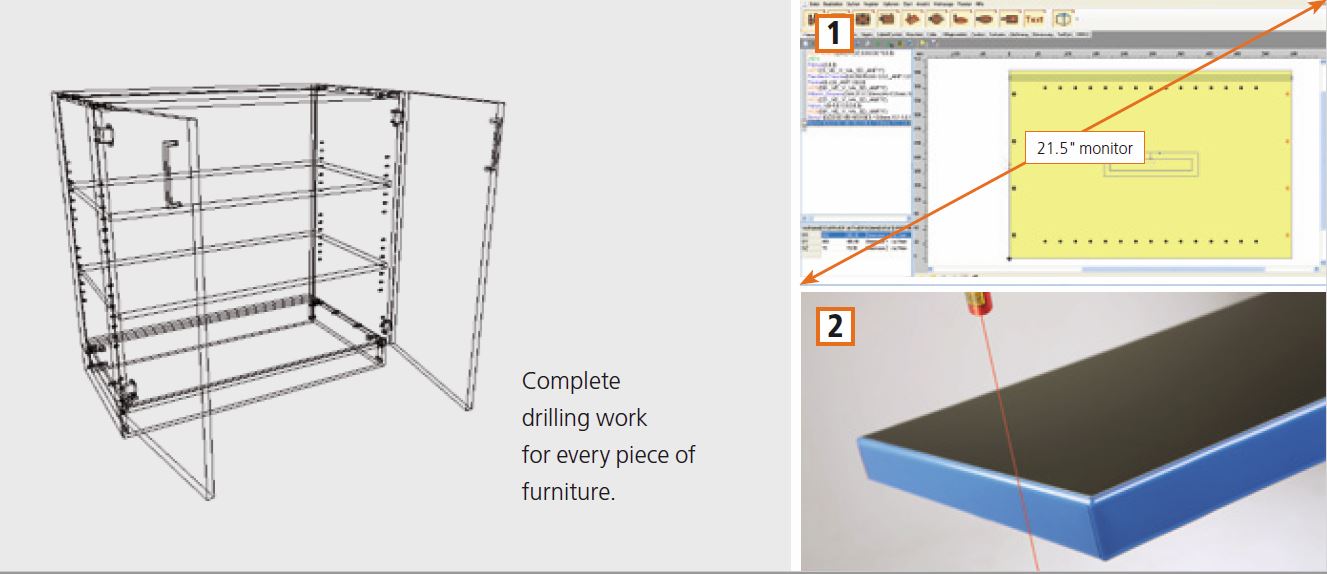

Your design ideas perfectly implemented

HOLZ-HER’s EVOLUTION Series ensures rational machining and maximum flexibility especially for production of furniture parts. And this, in spite of minimum space requirements.

- Simple programming

Equipped with a 21.5″ monitor (16:9) and latest version of the user-friendly CAMPUS/NC Hops Software including aCADemy CAD, DXF import and versatile macros (Fig. 1). - Innovative vacuum clamping system

Ideal for highly differing, even highly sensitive materials. Wide selection of suction cups e.g. for solid wood. - Enormous flexibility

Machining of panel material with length up to 2,500 mm and width up to 920 mm without additional extensions. Even workpieces with dimensions up to 200 x 70 mm are no problem. Fully automatic workpiece thickness adaptation from 8 to 70 mm – without setting up anew. - Automatic tolerance correction (optional)

Determination of exact length dimension and automatic correction of tolerances for dimension-dependent drilling. Ideal as perfect supplement for high precision drilling, e.g. for workpieces which have already been edged (Fig. 2).

The EVOLUTION 7403 from HOLZ-HER – Vertical CNC-Machining Center (Metric) from HOLZ-HER GmbH.